A kanban board structure may be designed by thinking of columns as verbs and cards as nouns

Posts

The role of the problem manager

Before I talk about what I think a problem manager should be doing, we might start by summarizing what problem managers typically do. Of course, every problem manager performs differently a role that each organization defines differently. So, I can only make a list of some of the major responsibilities of problem managers. Rare are […]

The Three Indicators

When managing work in an agile manner, we should consider three types of indicators: lead, lag and along.

Visualization of Configurations

In this article, I will delve into some of the issues associated with visualizing the configurations of systems.As with many other disciplines in service management, the use of visualizations in configuration management can be problematic. I hope to highlight some of these issues with a view toward: improving the functionality software developers build into configuration management; and expanding how consumers of configuration information make use of visualizations.

How to increase visualization maturity

We communicate information visually via a two-way street. BOth visualization designers and viewers must have similar levels of maturity to benefit from visualizations. This article suggest techniques for increasing the overall maturity of visualization techniques in an organizations.

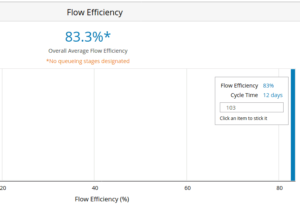

Measuring Flow Efficiency

A very low overhead method is proposed for accurately measuring flow efficiency with flow management software.

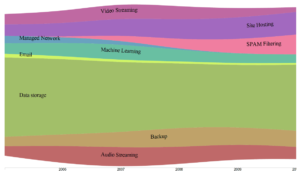

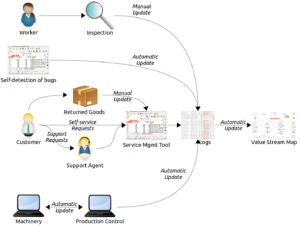

Automated Value Stream Maps

An automated value stream map is an advanced example of how information visualizations may be integrated into service system management tools.

Information Visualizations for Service Management

Service management tools include only rarely the visualizations that provide a high level of information to support the management of services. The reasons for this and many examples of high-level visualizations are provided.